Seebeck coefficient & specific resistance

Description

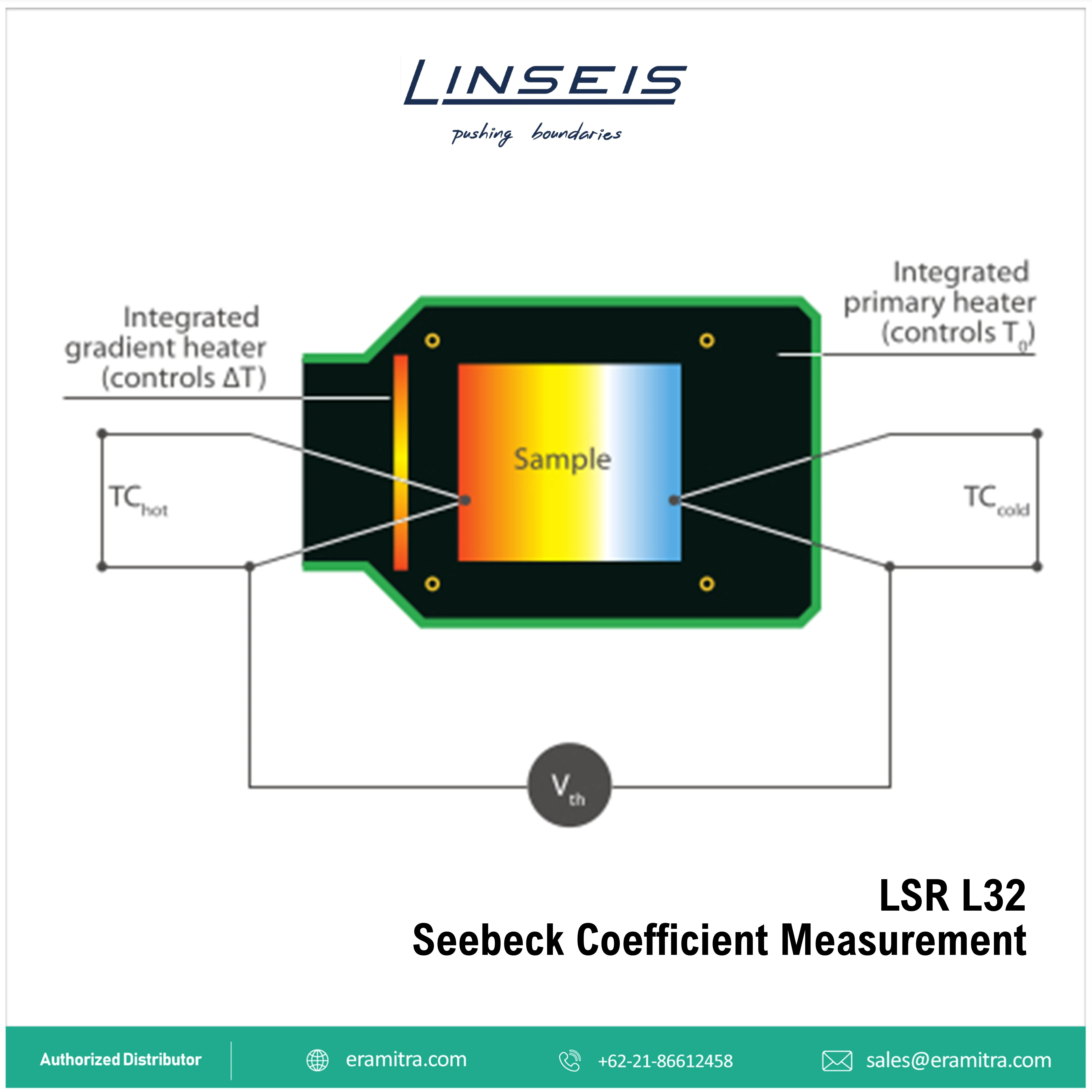

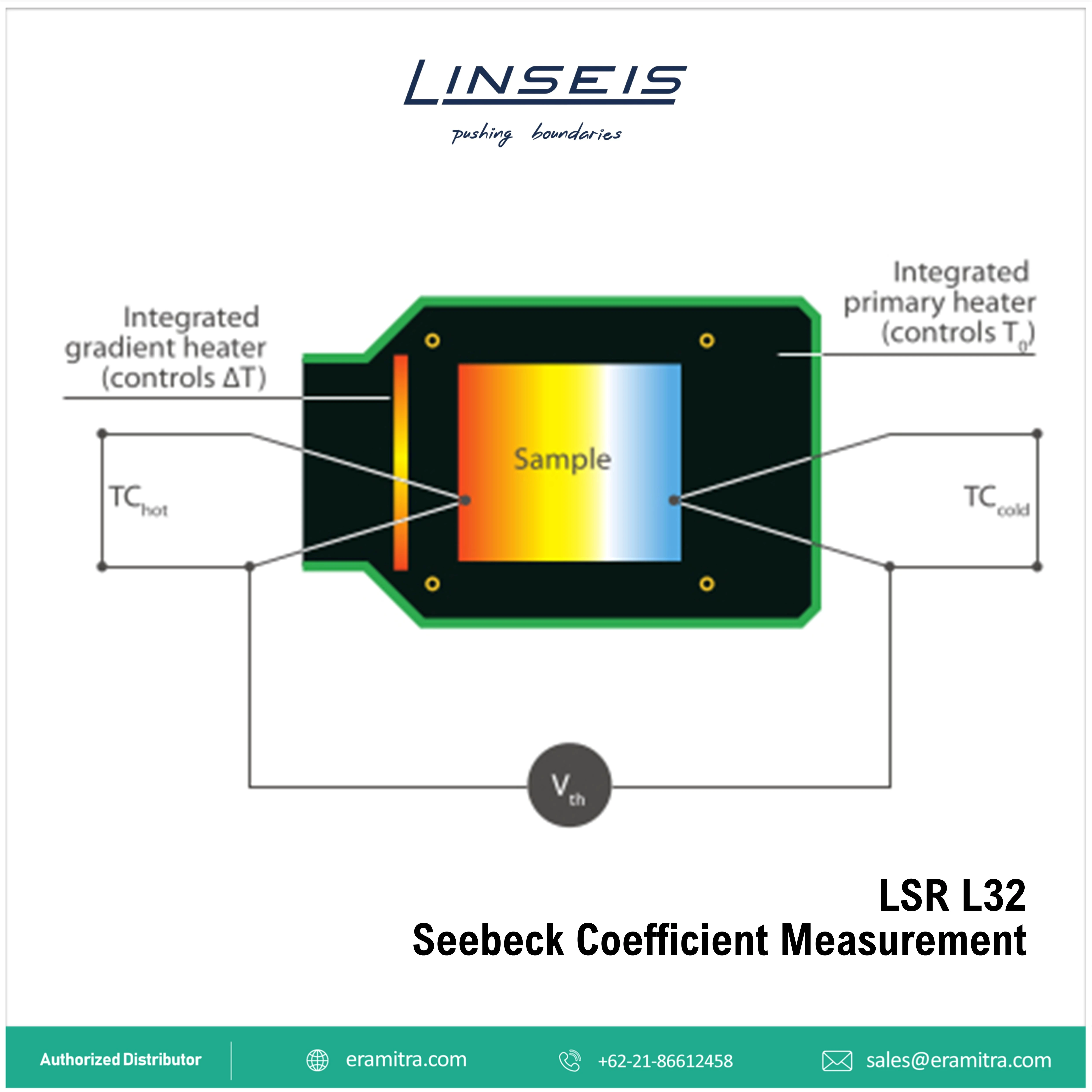

With the Linseis LSR platform, thermoelectric materials in the form of bulk materials and thin films can be characterized in a simple and convenient way. In the basic version – LSR-1 (LSR L32)- both the Seebeck coefficient and the electrical resistance can be measured fully automatically and simultaneously from -160°C to 200°C. The basic version of the LSR-1 (LSR L32) (RT to 200°C) can be combined with various options to extend the application range.

For example, the low temperature option enables fully automatic measurements with LN2 cooling down to -160°C and quench cooling down to 80 K (resistance only). An optional high-temperature probe stage enables resistance measurements up to 600°C.

The LSR-1 (LSR L32) system enables the characterization of metallic and semiconducting samples using the well-known Van der Pauw (resistance), static direct current and slope Seebeck coefficient measurement techniques. The compact table-top design enables fully automatic and software-controlled operation.

The comprehensive Windows-based software offers an easy-to-use user interface, including wizards for creating a measurement profile, feedback on the reliability of the measurement data and integrated measurement data evaluation and storage. The vacuum-tight measuring chamber in combination with a choice of gas dosing systems ensures that all application areas can be covered.

Special features

- Modular system design.

- Can be upgraded with gas purging system, lighting and cryogenic option.

- Vacuum-tight measuring chamber for measurements under defined atmospheres.

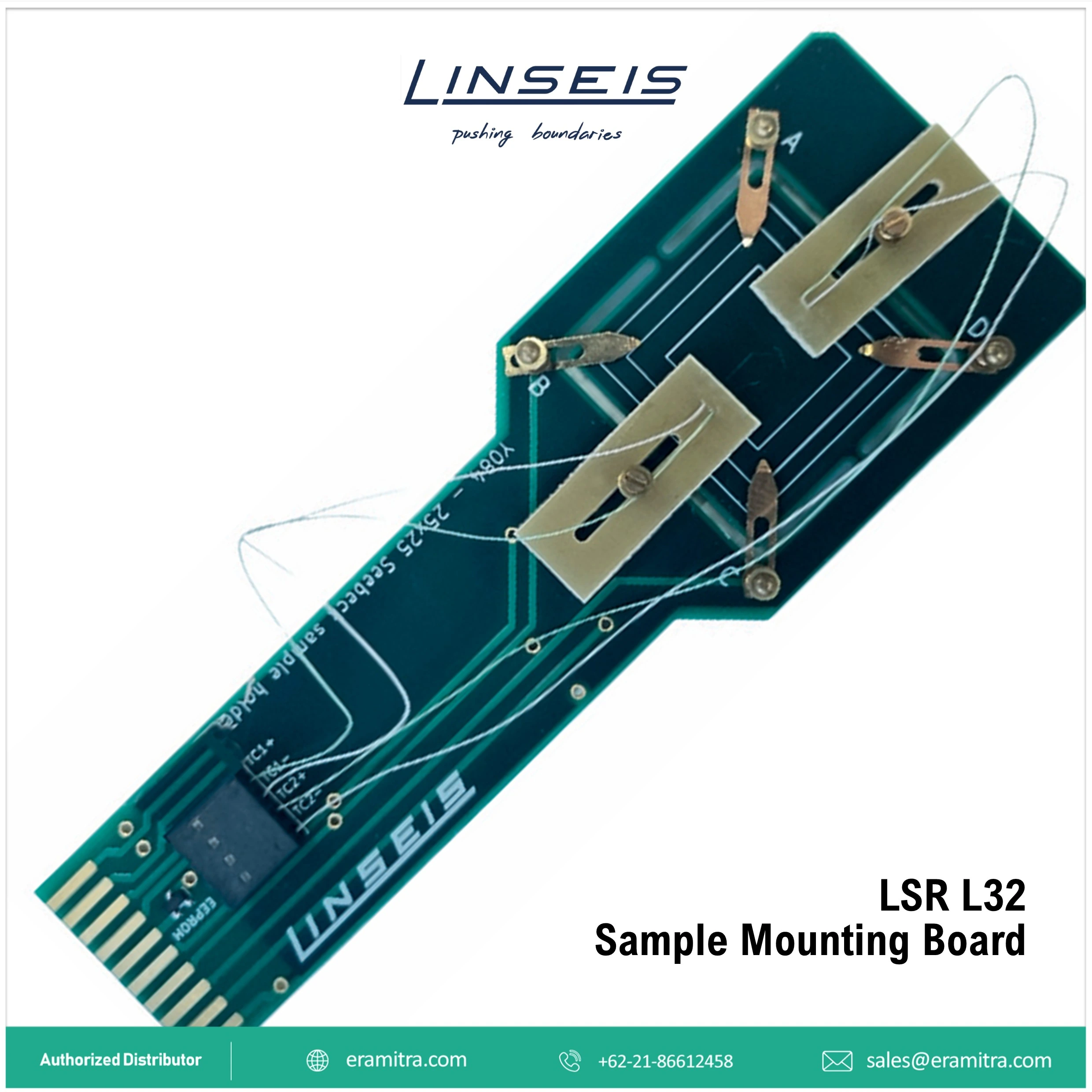

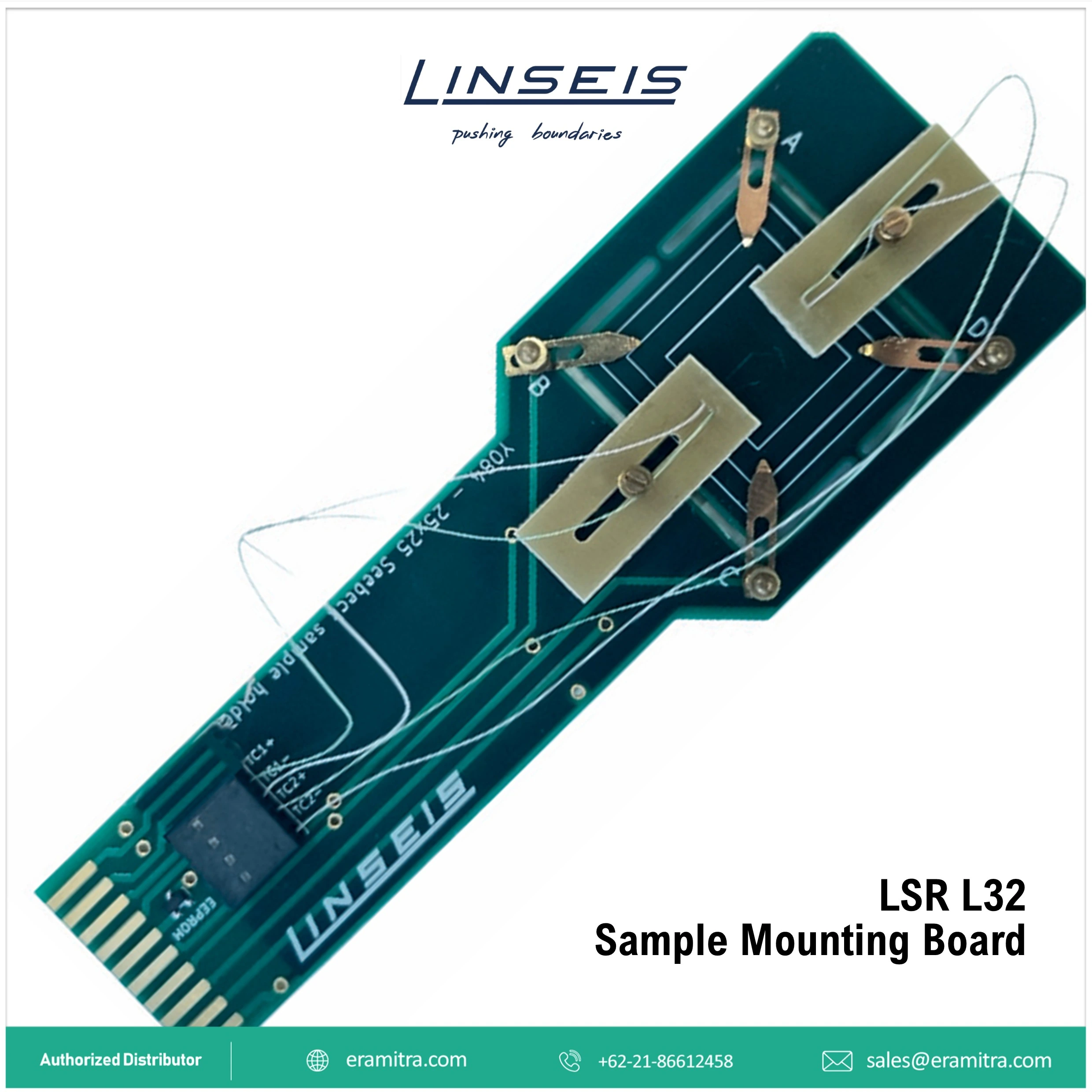

- Easy-to-use and interchangeable sample carriers with integrated primary and secondary heating.

- Integrated state-of-the-art measurement technology for the most accurate results with demanding samples.

- The unit can be used for simultaneous measurement of both the Seebeck coefficient and the electrical resistance (resistivity).

- The sample carrier uses a special contact mechanism for easy sample preparation and enables measurements with high reproducibility.

- V-I characteristic measurement can be performed to determine if the sensor has good contact with the sample.

- The system enables fully automatic, software-controlled measurements with predefined temperature and measurement profiles.

- The measured raw data is stored on the hard disk and can be exported in several data formats for further processing in Microsoft Excel or Origin.

- The system is supplied with Constantan reference including tables and certificate.